To help you understand if a DAF is the right fit for your wastewater treatment needs we have listed below some of the industries that are an ideal match for a DAF system.

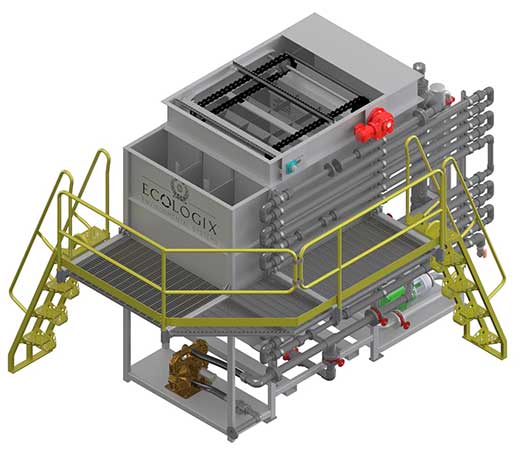

For over 10 years Ecologix has been designing, developing, fabricating, installing and optimizing a range of Dissolved Air Floatation (DAF) systems to fit our clients’ needs. In spite of our success, we have been relentless in the pursuit of improving our own systems and reducing our clients’ operation costs, maintenance, downtime and the elimination of odors and hazardous fumes. The culmination of these efforts is the ACE system.

Do you have a project you'd like assistance with?

Contact Ecologix Systems today for an engineered system quote specific to your project requirements.

Ecologix Environmental Systems is a world-class manufacturer and integrator of wastewater treatment equipment for the oil & gas, food, manufacturing, and automotive industries. Learn more About Ecologix.

Copyright @2022 Ecologix Environmental Systems, LLC | 11800 Wills Rd Alpharetta GA 30009 | 678-514-2100 | 888-326-2020 | www.EcologixSystems.com