Enhanced Dissolved Air Flotation (E-DAF) System

#1 - Quality Unsurpassed

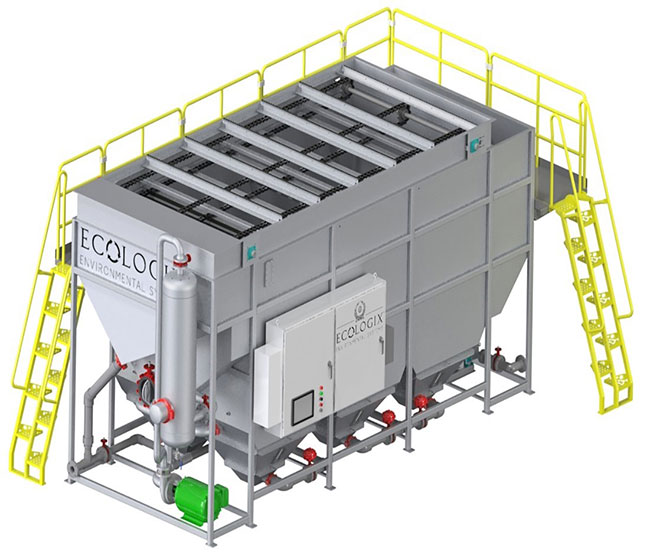

The Ecologix Enhanced DAF is a complete primary (phys/chem) treatment system. It is an incredibly versatile and efficient chemical precipitation and physical separation system. The E-DAF combines several proven technologies such as DAF (Dissolved Air Flotation) and DGF (Dissolved Gas Flotation), into a single platform. Our E Series Dissolved Air Flotation (DAF) systems are the industry standard for efficient removal of Fats, Oils and Grease (FOG), Total Suspended Solids (TSS) and Biochemical Oxygen Demand (BOD) from a wide variety of wastewater streams

What is Dissolved Air Flotation?

Key Features and Advantages

- Reduced footprint – Compared to any comparable system with similar flow rate/loading levels.

- High efficiency – Utilizes inclined settling tubes for increased surface area and faster separation.

- Air scouring – for automatic tube cleaning.

- Whitewater pumps – robust pumps in combination with saturation tanks provide industry leading reliability and low maintenance whitewater (dissolved air).

- Countercurrent scraping – for the most efficient separation of sludge from the effluent water. This also allows for more free water to decant prior to sludge removal.

- Sludge grating/thickening – Prevents sludge migration and thickens it.

- Fewer moving parts – no need for bottom auger and motor.

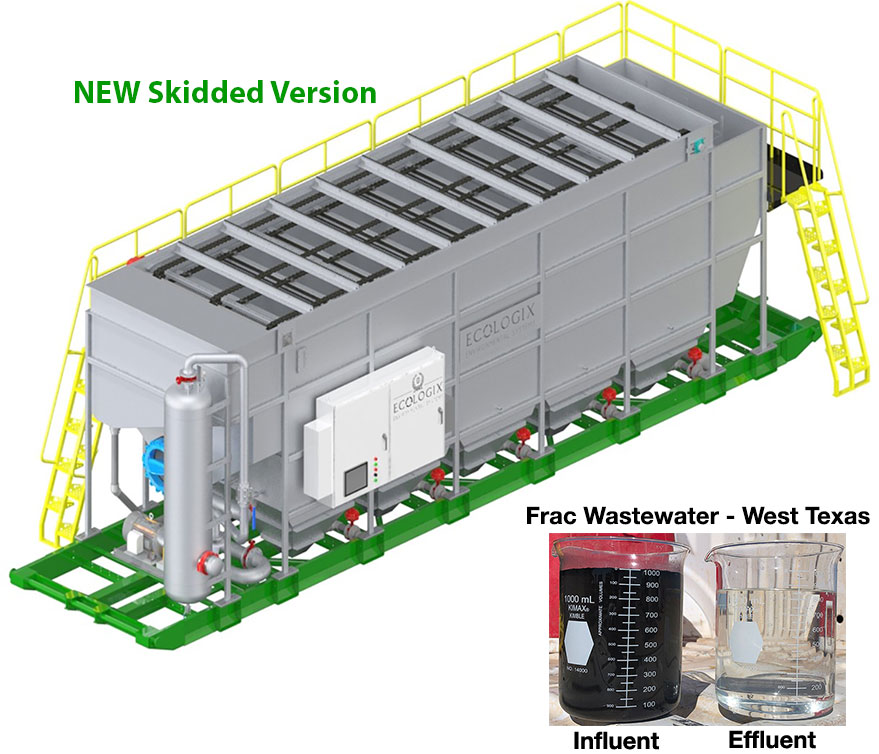

- Full movable SKID – An optional skid is now available with winch attachment.

Why Choose Ecologix for DAF Systems?

Preview the amazing results our E-DAF series can produce

Commercial bakery wastewater treatment.

Purifying frac wastewater in West Texas.

Key Features and Advantages

- DAF (Dissolved Air Flotation) and ACE (Air Charged Entrainment) combined into one – attached and entrained air for higher separation efficiencies.

- Upgradable to a full ITS (Integrated Treatment System) – including upgraded control panel, chemical feed pumps, polymer make down system, flocculation tubes, pre-wired and pretested as a complete wastewater treatment system.

- Easily converted to DGF (Dissolved Gas Flotation) for refineries and offshore platforms.

- Built from high corrosion resistant material such as 304SS or 316SS (upon request)

- Integrated walking mezzanine with stairs.

- Optional post-filtration filters.

- Optional dewatering system.

E Series DAF Available Models - Specifications

| Model | Max Flowrate* | L | W | H | Surface Area | ||||||

| US GPM | BPD | m3/h | ft | m | ft | m | ft | m | ft2 | m2 | |

| E-405 | 130 | 4,457 | 29.5 | 8' 2" | 2.5 | 5' 2" | 1.6 | 9' 4" | 2.8 | 202 | 18.8 |

| E-505 | 232 | 7,954 | 52.7 | 9' 8" | 2.9 | 6' 2" | 1.9 | 10' 10" | 3.3 | 362 | 33.6 |

| E-510 | 462 | 15,840 | 104.9 | 14' 7" | 4.4 | 6' 2" | 1.9 | 10' 10" | 3.3 | 722 | 67.1 |

| E-515 | 695 | 23,829 | 157.8 | 20' 1" | 6.1 | 6' 2" | 1.9 | 10' 10" | 3.3 | 1,085 | 100.8 |

| E-520 | 925 | 31,714 | 210.1 | 25' 6" | 7.8 | 6' 2" | 1.9 | 10' 10" | 3.3 | 1,445 | 134.2 |

| E-815 | 1,155 | 39,600 | 262.3 | 20 1" | 6.3 | 9' 2" | 2.8 | 10' 10" | 3.3 | 1,804 | 167.6 |

| E-820 | 1,540 | 52,800 | 349.7 | 26' | 7.9 | 9' 2" | 2.8 | 10' 10" | 3.3 | 2,405 | 223.4 |

| E-825 | 1,924 | 65,966 | 436.9 | 31' 6" | 9.6 | 9' 2" | 2.8 | 10' 10" | 3.3 | 3,006 | 279.3 |

| E-1025 | 2,313 | 79,302 | 525.3 | 32' 6" | 9.9 | 11' 2" | 3.4 | 10' 10" | 3.3 | 3,614 | 335.7 |

| E-1030 | 2,774 | 95,108 | 630 | 37' 11" | 11.6 | 11' 2" | 3.4 | 10' 10" | 3.3 | 4,335 | 402.7 |

| E-1035 | 3,237 | 110,982 | 735.1 | 43' 5" | 13.2 | 11' 2" | 3.4 | 10' 10" | 3.3 | 5,058 | 469.9 |

| E-1040 | 3,700 | 126,857 | 840.3 | 48' 10" | 14.9 | 11' 2" | 3.4 | 10' 11" | 3.3 | 5,780 | 537 |

| Model | Max Flowrate* | Recirculation Flowrate | Air Injection | |||

| US GPM | m3/h | US GPM | m3/h | SCFM | m3/h | |

| E-405 | 130 | 29.5 | 26 - 39 | 6 - 8.9 | 0.35 - 0.6 | 0.6 - 1.1 |

| E-505 | 232 | 52.7 | 46 - 70 | 11 - 15.8 | 0.62 - 1.1 | 1.1 - 1.9 |

| E-510 | 462 | 104.9 | 92 - 139 | 21 - 31.5 | 1.24 - 2.2 | 2.1 - 3.8 |

| E-515 | 695 | 157.8 | 139 - 209 | 32 - 47.4 | 1.86 - 3.3 | 3.2 - 5.7 |

| E-520 | 925 | 210.1 | 185 - 278 | 42 - 63 | 2.47 - 4.5 | 4.2 - 7.6 |

| E-815 | 1,155 | 262.3 | 231 - 347 | 52 - 78.7 | 3.09 - 5.6 | 5.2 - 9.4 |

| E-820 | 1,540 | 349.7 | 308 - 462 | 70 - 104.9 | 4.12 - 7.4 | 7 - 12.6 |

| E-825 | 1,924 | 436.9 | 385 - 577 | 87 - 131.1 | 5.14 - 9.3 | 10.5 - 18.9 |

| E-1025 | 2,313 | 525.3 | 463 - 694 | 105 - 157.6 | 6.18 - 11.1 | 10.5 - 18.9 |

| E-1030 | 2,774 | 630 | 555 - 832 | 126 - 189 | 7.42 - 13.3 | 12.6 - 22.7 |

| E-1035 | 3,237 | 735.1 | 647 - 971 | 147 - 220.5 | 8.65 - 15.6 | 14.7 - 26.5 |

| E-1040 | 3,700 | 840.3 | 740 - 1110 | 168 - 252.1 | 9.89 - 17.8 | 16.8 - 30.2 |

Enhanced Floctube System

Our innovative DAF system has the option to include an enhanced floctube assembly to increase contact time and improve dramatically system performance. Currently available configurations are listed below.

| Model | Pipe Diameter | Flowrate | Retention Time* | L | W | H | Chemical Feed Pumps (Add-On) | ||||||||

| Straights | Returns | Min (GPM) |

Max (GPM) |

Min (m3/hr) |

Max (m3/hr) |

For Min Flowrate (Seconds) | For Max Flowrate (Seconds) | ft | m | ft | m | ft | m | ||

| FLT-215 | 2" | 1 1/2" | 20 | 50 | 5 | 11 | 60 | 24 | 7' 2" | 2.2 | 2' 6" | 0.8 | 3' 4" | 1.0 | Additional 12" to Height |

| FLT-320 | 3" | 2" | 40 | 110 | 9 | 25 | 67 | 24 | 7' 5" | 2.3 | 3' 0" | 0.9 | 3' 11" | 1.2 | Additional 18" to Height |

| FLT-430 | 4" | 3" | 90 | 200 | 20 | 45 | 72 | 32 | 9' 8" | 2.9 | 2' 6" | 0.8 | 5' 3" | 1.6 | Additional 18" to Width |

| FLT-640 | 6" | 4" | 160 | 450 | 36 | 102 | 134 | 48 | 14' 8" | 4.5 | 3' 0" | 0.9 | 6' 10" | 2.1 | Additional 18" to Width |

| FLT-860 | 8" | 6" | 300 | 850 | 68 | 193 | 148 | 52 | 17' 8" | 5.4 | 4' 0" | 1.2 | 8' 2" | 2.5 | Additional 18" to Width |

| FLT-1080 | 10" | 8" | 600 | 1300 | 136 | 295 | 140 | 65 | 20' 8" | 6.3 | 5' 0" | 1.5 | 9' 7" | 2.9 | Additional 18" to Width |

| FLT-1210 | 12" | 10" | 900 | 2000 | 204 | 454 | 150 | 68 | 23' 8" | 7.2 | 6' 0" | 1.8 | 10' 11" | 3.3 | Additional 18" to Width |

* Retention time is calculated based on a minimum velocity of 2ft/second to avoid solids settling

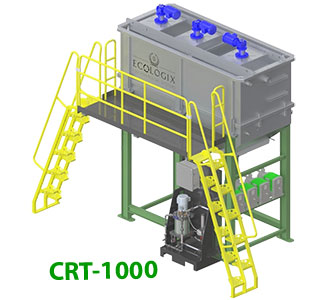

Chemical Reaction Tanks

We also provide the option of adding separate chemical reaction tanks to our Enhanced DAF System.

- Easy Operation

- Greater flexibility for varying flow rates

- Enhanced efficiency

Chemical Reaction Tanks Models

| Model | L | W | H | Retention Time (Mins) DAF Model |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ft | m | ft | m | ft | m | 405 (130 GPM) |

505 (232 GPM) |

510 (462 GPM) |

515 (695 GPM) |

520 (925 GPM) |

815 (1155 GPM) |

820 (1540 GPM) |

825 (1924 GPM) |

|

| CRT-1000 | 10' | 3.0 | 4' 2" | 1.3 | 11' 10" | 3.6 | 7.69 | 4.31 | 2.16 | 1.44 | 1.08 | 0.87 | 0.65 | 0.52 |

| CRT-1900 | 12' 1" | 3.7 | 5' 7" | 1.7 | 11' 10" | 3.6 | 14.62 | 8.19 | 4.11 | 2.73 | 2.05 | 1.65 | 1.23 | 0.99 |

| CRT-3400 | 12' 1" | 3.7 | 5' 7" | 1.7 | 11' 10" | 3.6 | 26.15 | 14.66 | 7.36 | 4.89 | 3.68 | 2.94 | 2.21 | 1.77 |

| CRT-5200 | 12' 1" | 3.7 | 8' 6" | 2.6 | 11' 10" | 3.6 | 40.00 | 22.41 | 11.26 | 7.48 | 5.62 | 4.50 | 3.38 | 2.70 |

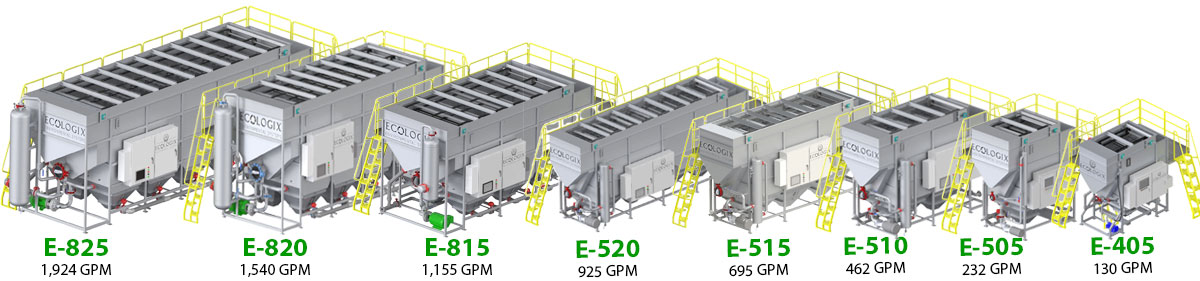

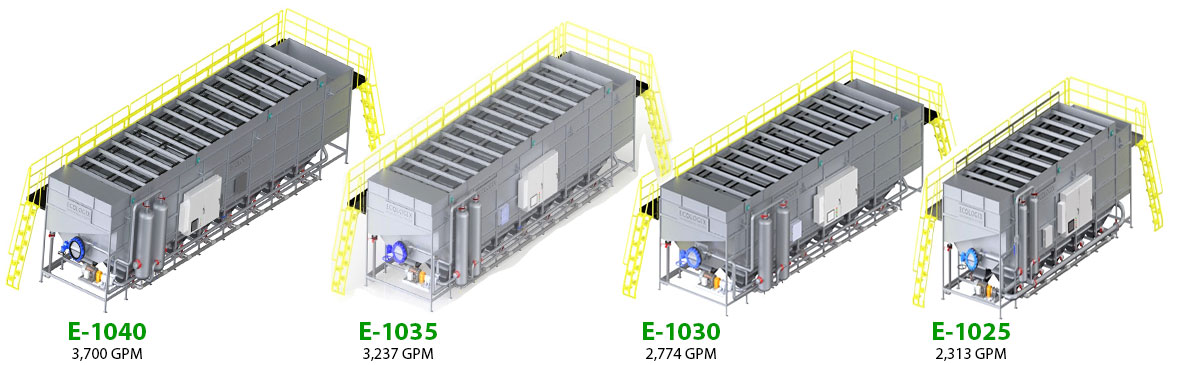

E-DAF Series - 12 Models - Same Excellent Performance

Our E-DAF Series models from the E-405 all the way up to the E-1040. These models range in flowrate capacities of 130 to 3,700 GPM.

Our E-DAF 10 Series lineup.

E-DAF Compact Models

Take a closer look at our super compact DAF models that outperform any comparably sized DAF in the marketplace today.

E-405

E-505

E-510

DAF System Applications

The following is a sampling of applications that we have successfully deployed DAF systems.

- Meat processing / slaughterhouse (beef, pigs, sheep, goats)

- Ice Cream factory

- Poultry processing (chickens, turkey, duck, geese)

- Confectionary/Candy manufacturing

- Bakery / baked goods

- Oil & Gas industry

- Mining industry

- Automotive industry

- Printing manufacturer (ink removal from wastewater)

- Cereal and snack foods

- Food processing and packaging

- Dairy processing (milk, cheese, yogurt)

- Beverage factories (breweries, juice, soda)

- Paper and pulp industry

- Metal plating and finishing

- Biochemical industry

- Recycling of glass, plastics, paper

- Egg processing

Client Testimonials

“We have been very satisfied with the overall install and operational performance of our Ecologix DAF. By far it is the most simple to use and automated DAF system that we have encountered on the market. Ecologix provided an economical turnkey system that has exceeded expectations.” Aaron Riedell, Vice President of Operations at Revela Foods

Revela Foods is a diversified food ingredients and processed foods company. Our passion for people and flavor innovation are at the heart of what we do. Our simple approach and efficient systems ensure a seamless, uncomplicated experience from start to finish. Ecologix Environmental Systems has contributed to Revela Foods ongoing mission to harness cutting edge technology in their wastewater treatment operations for the removal of solids and other contaminants (e.g., our cheese dairy production line), by providing Revela Foods with our state of the art Enhanced Dissolved Air Flotation (E-DAF).

Oil Field Installation Photos