OrganoClay MCM-830P

The MCM-830P Difference

The main difference between Ecologix OrganoClay – MCM-830P and other organoclays is that our media is 100% non-swelling modified clay and does not require blending with anthracite for porosity in a filter bed. This means that filter beds typically run 2-3x longer than filters using competitive (30/70 and 40/60 – clay/anthracite blends). In addition, because Ecologix OrganoClay – MCM-830P has a greater amount of “actives,” it may also remove contaminants present at lower levels better than competitive medias.

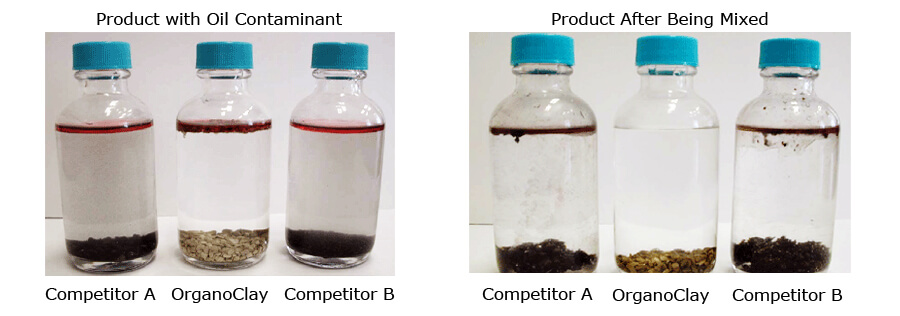

MCM-830P OrganoClay is a powerful, selective adsorbent that will recognize hydrocarbons and other pollutants – but not water. Designed for use in conventional liquid-phase filtration vessels, the granular modified clay attracts contaminants like a magnet and locks them in its molecular structure. MCM-830P Modified Clay Media is produced in a proprietary process by combining sodium montmorillonite clay with a cationic quaternary amine salt, which replaces adsorbed sodium by ion exchange. Resulting clay surfaces become organophilic.

Extensive application use and field testing of MCM-830P Modified Clay Media technology, verified by independent laboratories, has demonstrated removal of a wide range of contaminants to discharge levels which meet NPDES and other regulatory requirements.

OrganoClay MCM-830P Properties

| Appearance | Specific Gravity | Bulk Density | Granule Size | Contact Time | Void Volume |

| Gray to Tan granules | 2.0 - 2.2 | 42 - 46 lbs/ft cubed | 8/30 Mesh (US sleeve) | 2 - 4 minutes (EBCT 3.3 - 6.6 min.) | 35% - 45% |

Water Treatment

Field testing and project implementation have consistently revealed that the combination of MCM-830P and granular activated carbon effectively removed hydrocarbons from produced water. Treated in field testing revealed specific findings:

- Reduces Total Petroleum Hydrocarbons to non-detectable levels. Sampling reveals TPH below detectable limits after adsorption by MCM-830P.

- Reduces Oil and Grease to non-detectable levels. Samples show Oil and Grease below detectable limits after adsorption by MCM-830P alone.

- Reduced soluble hydrocarbons Benzene, Ethylbenzene, Toluene, and Xylene to barely detectable levels. In samples BTEX was barely detectable after adsorption by MCM-830P alone. BTEX was below detectable limits after the combination of MCM-830P and granular activated carbon.

In simple terms, MCM-830P eliminated hydrocarbon contamination from produced water during the test. Other testing has shown that these results are consistent across large-scale commercial applications.

Effective Water Treatment with Minimal Cost

Other laboratory testing of spent MCM-830P has shown that BTEX and other volatile hydrocarbons are adsorbed tightly enough for the spent product to pass the EPAs Toxicity Characteristic Leachate Procedure (TCLP) test and be disposed as a non-hazardous waste. The TCLP is used to identify the presence or absence of toxic chemicals that might be able to leach into groundwater after disposal. Being classified as a non-hazardous waste may allow the spent product to be landfilled, land farmed, or otherwise disposed in an economical and ecologically proper manner.

Organoclay Benefits/Usage

OrganoClay - A Cost Saving Filtration Media

OrganoClay Increases the Efficiency of the Treatment Process

Stand Alone

Post Treatment

Application

Pre-Treatment

Dosage

Storage and Handling

Hydrocarbon Removal with OrganoClay

OrganoClay Performance

| Sample Constituent | Projected: Before | Projected: After | Result: % Reduction | Source Type |

| Acenaphthene | 5,580.0000 | BDL | 99.99% | Creosote Plant |

| 0.1500 | 0.0005 | 99.67% | Wood Processing | |

| Acenaphthylene | 0.0067 | ND | 99.99% | Wood Processing |

| Aluminum | 0.100 | 0.0200 | 80.00% | Chemical Plant |

| Ammonia Nitrogen | 245.0000 | 21 | 91.43% | Paper Mill 2 |

| Anthracene | 3.9580 | ND | 99.99% | Carbon Black Plant |

| 3,650.0000 | BDL | 99.99% | Creosote Plant | |

| 0.0134 | ND | 99.99% | Wood Processing | |

| Arsenic | 2.6200 | 0.1220 | 95.34% | Oil Production |

| 0.2130 | 0.0130 | 93.90% | Creosote Plant | |

| Benzene | 9.8000 | 0.2300 | 97.65% | Natural Gas Well |

| Benz (a) Anthracene | 1,170.0000 | BDL | 99.99% | Creosote Plant |

| 0.0001 | ND | 99.99% | Wood Processing | |

| Benzo (b) Fluoranthene | 0.0001 | ND | 99.99% | Wood Processing |

| Benzo (a) Pyrene | 0.0360 | ND | 99.99% | Carbon Black Plant |

| Benzo (g,h,i) Perylene | 0.0380 | ND | 99.99% | Carbon Black Plant |

| BOD's | 244 | 11 | 95.49% | Firefighting Academy |

| 1,100.0000 | 9 | 99.18% | Laundry Service | |

| 211,000.0000 | 533 | 99.75% | Paper Mill 3 | |

| 113,400.0000 | 849 | 99.25% | Creosote Plant | |

| 23,689.0000 | 2,133 | 91.00% | Paper Mill 1 | |

| BTEX | 1.0000 | 0.0270 | 97.30% | Shipyard |

| 20.4900.0000 | ND | 99.99% | Firefighting Academy | |

| Cadmium | 0.0220 | BDL | 99.99% | Laundry Service |

| 4-Chloro-3-Methylphenol | 26.0000 | ND | 99.99% | Process Coolant |

| Chromium | 0.0780 | ND | 99.99% | Laundry Service |

| 2.0200 | 0.0080 | 99.60% | Creosote Plant | |

| 24.8000 | 4.3100 | 82.62% | Braking Systems | |

| Chrysene | 10,7000.0000 | BDL | 99.99% | Creosote Plant |

| 0.0001 | ND | 99.99% | Wood Processing | |

| Cobalt | 1.5200 | 0.0300 | 98.03% | Chemical Plant |

| COD's | 3,340.0000 | 113 | 96.62% | Firefighting Academy |

| >23,000.0000 | 458.0000 | 98.01% | Paper Mill 3 | |

| 87,200.0000 | 949.0000 | 98.91% | Paper Mill 2 | |

| Copper | 4.0000 | 0.0220 | 99.45% | Shipyard 1 |

| 0.2520 | BDL | 99.99% | Laundry Service | |

| 1.5600 | 0.0530 | 96.60% | Creosote Plant | |

| 1,1 Dichloroethane | 0.0150 | ND | 99.99% | Groundwater |

| 0.0094 | ND | 99.99% | Groundwater | |

| 1,2 Dichloroethene | 1.5000 | ND | 99.99% | Groundwater |

| 1,4 Dioxane | 726.5000 | 126 | 82.66% | Plastics Mfr. |

| Ethylbenzene | 1.6000 | 0.0073 | 99.54% | Natural Gas Well |

| Fluoranthene | 4.3930 | ND | 99.99% | Carbon Black Plant |

| 95,400.0000 | BDL | 99.99% | Creosote Plant | |

| 0.0057 | 0.0001 | 97.44% | Wood Processing | |

| Fluorene | 59,900.0000 | BDL | 99.99% | Creosote Plant |

| 0.0789 | ND | 99.99% | Wood Processing | |

| Gasoline Range Hydrocarbons | 1.8800 | ND | 99.99% | Process Coolant |

| Lead | 2.0000 | 0.0110 | 99.45% | Shipyard 1 |

| 4.1800 | BDL | 99.99% | Laundry Service | |

| Manganese | 5.7500 | 0.4000 | 93.04% | Chemical Plant |

| Mercury | 0.0018 | ND | 99.99% | Oil Production |

| 2-Methylnaphthalene | 6.1000 | ND | 99.99% | Creosote Plant |

| Motor Oil | 310 | ND | 99.99% | Process Coolant |

| Naphthalene | 1.0000 | ND | 99.99% | Shipyard 1 |

| 21,400.0000 | BDL | 99.99% | Creosote Plant | |

| 0.6830 | 0.0008 | 99.89% | Wood Processing | |

| Nickel | 2.0000 | 0.1600 | 92.00% | Shipyard 1 |

| 0.0200 | ND | 99.99% | Oil Production | |

| 0.0840 | BDL | 99.99% | Laundry Service | |

| Oil and Grease | 200 | ND | 99.99% | Shipyard 1 |

| 488 | ND | 99.99% | Tank Cleaning | |

| 289,000.0000 | 3.4600 | 99.99% | Laundry Service | |

| 147,000.0000 | 3.4600 | 99.99% | Paper Mill 3 | |

| 68,800.0000 | BDL | 99.95% | Creosote Plant | |

| 3,360.0000 | 1.6600 | 97.78% | Paper Mill 1 | |

| 2,050.0000 | 45.6000 | 99.99% | Braking Systems | |

| 1.0000 | ND | 99.99% | Wood Processing | |

| PCP (Pentachlorophenol) | 4,630.0000 | BDL | 99.99% | Creosote Plant |

| 2.4500 | 0.1300 | 94.69% | Wood Processing | |

| Phenanthrene | 15,900 | BDL | 99.99% | Creosote Plant |

| 0.0888 | 0.0001 | 99.90% | Wood Processing | |

| Phenolics (recoverable) | 2.0000 | 0.1550 | 92.25% | Shipyard 1 |

| Phosphourus | 3.5000 | 0.2000 | 94.29% | Chemical Plant |

| Pyrene | 16.1570 | ND | 99.99% | Carbon Black Plant |

| 42,700.0000 | BDL | 99.99% | Creosote Plant | |

| 0.0028 | 0.0001 | 96.19% | Wood Processing | |

| TCE (Trichloroethene) | 0.1800 | BDL | 99.99% | Landfill Groundwater |

| 2.8000 | ND | 99.99% | Groundwater | |

| TCE (Trichloroethylene) | 250.0000 | 2.2000 | 99.12% | Pesticide Mfr. |

| TOC (Total Organic Compounds) | 86,000.0000 | 1,370 | 98.41% | Paper Mill 1 |

| Toluene | 26.0000 | 0.0200 | 99.92% | Natural Gas Well |

| TPH (Total-Petroleum Hydrocarbons) | 50.0000 | ND | 99.99% | Firefighting Academy |

| Total Phosphorous | 132.0000 | 3.2 | 97.58% | Paper Mill 2 |

| TSS's | 93.0000 | 10 | 89.25% | Firefighting Academy |

| 500.0000 | 9 | 98.20% | Laundry Service | |

| 27,400.0000 | 43 | 99.84% | Paper Mill 2 | |

| 57,250.0000 | 58 | 99.90% | Creosote Plant | |

| Vinyl Chloride | 0.2600 | ND | 99.99% | Groundwater |

| Xylene (m & p) | 14.000 | 0.0076 | 99.95% | Natural Gas Well |

| Xylene (o) | 3.5000 | 0.0013 | 99.96% | Natural Gas Well |

| Zinc | 4.0000 | 0.7430 | 81.43% | Shipyard 1 |

| 0.0460 | 0.0150 | 67.39% | Oil Production | |

| BDL | 99.99% | Laundry Service |

Product Specifications

| Bulk Density | 46 lbs./cu.ft. |

| Specific Gravity | 1.5-2.5 |

| pH Range | 2-12 |

| Temperature Range | 33-180ºF |

| Flash Point | +400ºF |

| Contact Time | 3 minutes actual retention time 9 minutes EBCT (at 80% fill) |

| Typical Usage Recommendations | |

| Typical Applications: - Removal of Oil & Grease - insoluble hydrocarbons from wastewater or ethylene glycols |

|

Specialty Chemicals

Filtration Media