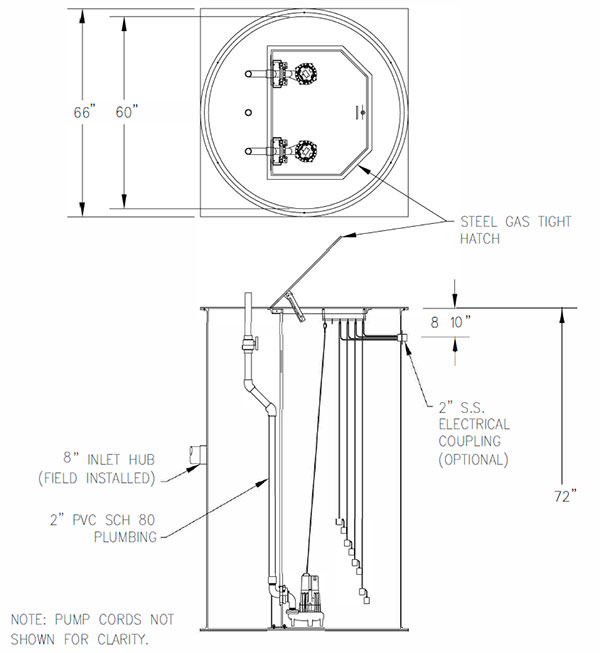

Wastewater Lift Station

Ecologix lift stations include dual, auto-reversing grinder pumps with trimmed impellers, installed within a fiberglass basin. Our lift stations include all internal piping, aluminum gas tight hatch cover, mechanical floats and control panel.

Components of the Ecologix Lift Station Package

The lift station package contains a basin, pumps and control panel

Basin

- Ideal for commercial and industrial applications

- Available in high-density polyethylene structural foam (PSF), polyethylene or fiberglass

- Complete with necessary sealing hardware and flanges

- Available with 2″ or 3″ vent and 2″ or 3″ discharge

- Lid with gasket and 4″ cast iron inlet hub with anti-corrosion coating are included with the sewage basins

- Centerline of hub is located 10-1/2″ (26.7 cm) from top of basin (standard). Custom locations available

- Polyethylene sewage pump basins are IAPMO approved.

- Sealed (radon) basins for sump pumps in 18″ x 22″ (45.7 x 55.9 cm) and 18″ x 30″ (45.7 x 76.2 cm) sizes

- Polyethylene sump basin available with plastic unsealed covers in 18″ x 22″ (45.7 x 55.9 cm)

- Sewage basins are watertight and gas-tight when properly installed

- Durable steel cover with gasket standard on simplex and duplex sewage basins

- One piece, seamless construction on all basins

- Duplex covers include two pump plates and inspection plate

- Ready to install for economical and simple installation

- Dimensional engineering data available

- Temperature rated 130 oF (54 oC)

- Fiberglass models available that will pass the 10′ (3 m) water stack test.

Grinder Pumps

Material Features

- 440 stainless steel cutter and plate hardened to Rockwell C55-60

- Discharge size – 1¼” NPT

- Seals – dual mechanical carbon/ceramic upper, carbon/silicon carbide lower

- Moisture detection system

- Construction – Cast iron ASTM A-48, Class 30, 30,000# tensile strength, protected with a corrosion resistant baked on epoxy powder coating

- Attaching hardware – 304 stainless steel

- O-ring seals – Viton

- Impeller – Bronze vortex design

Motor Features

- 2 – 50 HP

- 1 Phase – 200/230 Volt

- 3 Phase – 200/230/460/575 Volt

- Stator – Class F insulation and lead wires Nema B design

- Thermal sensor with leads

- Housing – Cast iron, oil-fi lled

- Ball bearings – Upper and lower high carbon chromium steel

- Power and sensor cable length – 20′