MBBR Wastewater Treatment System

Moving Bed Biofilm Reactor (MBBR) systems, originally invented by the Norwegian University of Science and Technology in 1989, consist of an aerated treatment tank (similar to a activated sludge tank) with special plastic media or carriers that provide a surface promoting biofilm growth. The media are made of a material with a density close to the density of water (1 g/cm3). An example is high-density polyethylene (HDPE) which has a density close to 0.95 g/cm3.

An MBBR system is a continuously operating, non-clogging biofilm reactor with low head loss, a high specific biofilm surface area, and no requirement for periodic backwashing.

The media provides increased surface area for the biological microorganisms to attach to and grow in the aeration tanks. The biofilm media is continuously agitated by air bubbles generated by the aeration system integrated into the MBBR.

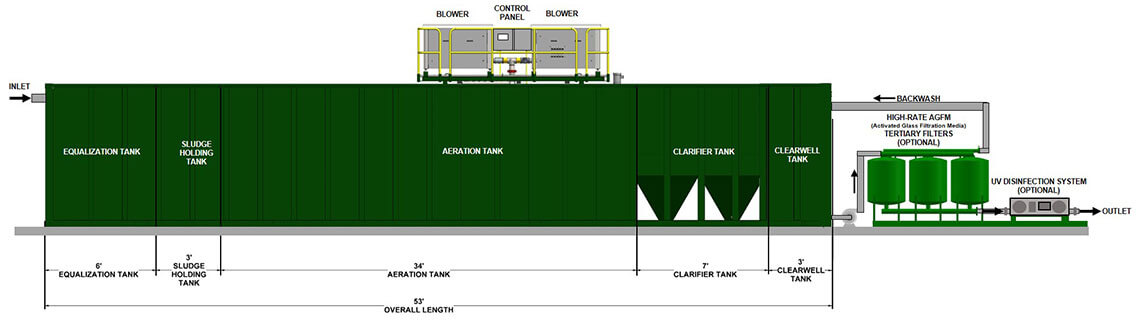

53 Ft, Dual Clarifier MBBR

Industry Applications

Industries

- Oil & Gas

- Dairy

- Food & Beverage

- Bakeries

Pollutant Removal

- BOD, COD Removal

- Nitrification

- Ammonia Removal

- Total Nitrogen Removal

Typical Expected Removal Rates

| Pollutant | Removal Rate | Typical Municipal Discharge Limits |

|---|---|---|

| TSS | 80% | Lower than permissible limit |

| TDS | 60% | Lower than permissible limit |

| COD | 80% | Lower than permissible limit |

| BOD | 90% | Lower than permissible limit |

| FOG (Oil & Grease) | 90% | Lower than permissible limit |

| NO3-N | 85% | |

| PO4- | 90% |

MBBR Advantages

MBBR systems possess distinct advantages over traditional activated sludge systems including:

- Smaller footprint required (due to larger surface area provided by biofilm media)

- Higher effective sludge retention time (SRT) which is favorable for nitrification

- Lower sludge production

- Bakeries improved settling characteristics

- Operation at higher suspended biomass

- Ability to respond to load fluctuations

- Simple operation and maintenance

- Durable and stable

- No need for periodic backwashing

- Easily expanded as requirements change