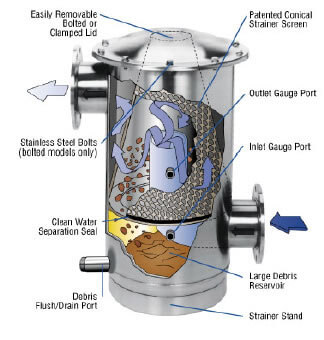

Cone Filters for Wastewater Treatment

Cone Filters are used to catch and filter any type of debris from a waste stream. A variety of mesh screens are available to remove micron-sized particulates as well as larger, 1/4″ sized particles. The cone filter has been highly successful in many applications such as pumping from wells and sump pumps.

System Overview

Choosing a filter with sufficient surface area is critical in any application. The Cone Filter series has significantly more surface area than most traditional basket and y-strainers. Ecologix has a filter that will fit your specific needs with units available from 2″ to 10″ and flow rates up to 2,000 GPM (higher flow rates are achieved by manifolding multiple filters). Our screen mesh options are available from 16 to 250 mesh.

Cone Filter Instumentation & Housing (all models)

- T304 Stainless Steel

- T316 Stainless Steel Available By Special Order

- Screen Frames: T304 Stainless Steel

- Screen Mesh: T316 Stainless Steel

- Perforated Sheet Metal: T304 Stainless Steel Piping

- 2” and 3” Models Use a Type 304 Stainless Steel Riser Pipe

- 4” Through 10” Models Use a PVC Elbow and Riser Pipe Assembly

- CPVC is Available By Special Order

- Stainless Steel is Also Available By Special Order

Gaskets

- EPDM is Standard, Other Compounds Are Available By Special Order

- Gaskets Include: Lid Gasket, Disk Gasket and Filter Gasket (bottom gasket)

- Bolt, Washer and Nut: Grade 5 mp Assembly (clamped lid models only)

- Clamp and Handle: T304 Stainless Steel

- 1/4” FNPT T304 Stainless Steel Inlet & Outlet Gauge Ports Are Standard (gauges not included)

Cone Filter Specifications

| Model | Max gpm | Screen Surface Area | Inlet/Outlet Style | Flush Port Connection | Lid Type | Max. Pressure Rating |

| CF-2 | 100 | 122 sq. in. | 2" Male NPT | 1.5" Male NPT | Clamp | 125-PSI |

| CF-3 | 200 | 200 sq. in. | 3" Male NPT | 1.5" Male NPT | Clamp | 125-PSI |

| CF-4C | 350 | 367 sq. in. | 4" Flanged | 1.5" Male NPT | Clamp | 125-PSI |

| CF-4B | 350 | 367 sq. in. | 4" Flanged | 1.5" Male NPT | Bolt | 150-PSI |

| CF-6 | 750 | 745 sq. in. | 6" Flanged | 1.5" Male NPT | Bolt | 150-PSI |

| CF-8 | 1300 | 1559 sq. in. | 8" Flanged | 1.5" Male NPT | Bolt | 150-PSI |

| CF-10 | 2000 | 2434 sq. in. | 10" Flanged | 1.5" Male NPT | Bolt | 150-PSI |

Pressure Differential Alarm Package (PDA)

The Pressure Differential Alarm Package (PDA) continously monitors the inlet and outlet system pressure. When the filter screen becomes dirty, a switch-gauge triggers an aubible siren and visual flashing alarm. These alarms are intended to alert maintenance personnel that the strainer screen needs to be removed from the strainer housing for manual cleaning.

The Automatic Timer Flush Package (ATF-EA-1.5) ensures that particulates that fall down into the debris reservoir are automatically flushed. The power supply and timer controls for the valve package are housed inside the watertight control box, attached to the valve. Depending on the application, the end-user simply dials in the flush frequency and flush duration of the valve. Based on the programmed parameters, the ball valve quickly opens and closes, minimizing the volume of water that is flushed from the strainer. The valve also comes with a manual flush control switch that can be used to conveniently manually flush the strainer or drain the strainer before removing the screen.