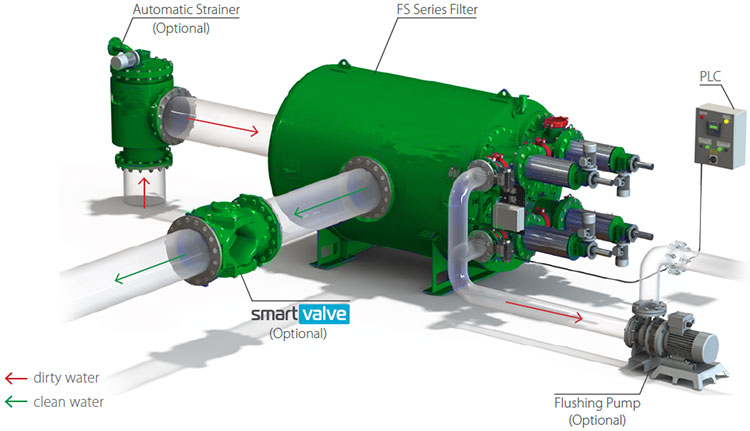

Multi Screen Automatic Filters

Reliable filtration down to 10 μm, flow rates from 3,000 – 9000 m3/hr in a single unit. Efficient removal of high volumes of TSS and organic matter including macro fouling. Skid mounted and standby functionality also available.

Unique Features

- Produced Water

- Intake water filtration

- Water injection filtration down to 10 μm

- Oil & Gas pipeline flushing

- Protection of cartridge filters

- General Purpose sea water filtration

Applications

- Oil & Gas

- Power & Energy

- Water Reclamation & Desalination

- Municipal Water Treatment

- Agriculture

- Additional Industrial

FS Series Details

| Construction Materials | |

| Pressure Vessel Housing & Lid | Carbon Steel / Stainless Steel / SDSS |

| Pressure Vessel Coating | Powder Coated, Wet Paint / Internal Rubber Lining |

| Screen Type | FS smartweave 4-layer Sintered Weaved Screen |

| Cleaning Mechanism | 316L / SMO254 / POM |

| Flush Valve | SS 316 / Marine Bronze |

| Seals | Viton / Synthetic Rubber / EPDM |

| Internals | SS316 / POM/ PPH / SMO254 |

| Additional Data | |

| Annual Design Flush Cycles | 50,000 |

| Design Temperature | 60oC / 140F |

Automatic Screen Filter Technology Explained

- Enhanced strength & durability

- Multi-layered sintered structure

- Available screens: 10-100 or 500 μ

- Available material: 316L, 904L

- 100% screen cleaning

- Zero wear on the filter screen

- Improved flow rate and shorter ballasting process

- Autonomous self-cleaning filtration cycle

- No back washing sequence

- Minimal water required for flushing

- Low operating pressure

- Continuous robust automatic operation

Available Models

* Turbo and Super Turbo options provide additional cleaning capabilities as well as high amount of flushing capacity.| Model | In/Out Connections | *50 μm Screen Max. Flow rates | *50 μm Flushing Flow Rate | *40 μm Screen Max. Flow Rates | *40 μm Flushing Flow Rate | *25 μm Screen Max. Flow Rates | *25 μm Flushing Flow Rate | Weight (kg) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | mm | US gpm | m3/hr | m3/hr | US gpm | m3/hr | m3/hr | US gpm | m3/hr | m3/hr | Dry | Wet | |

| FS-603H/V | 16-18 | 400-500 | 7,925 | 1,800 | 68 | 6,604 | 1,500 | 68 | 4,403 | 1,000 | 63 | 2,910 | 5,810 |

| FS-804H/V | 18-20 | 450-500 | 10,567 | 2,400 | 91/45 | 8,806 | 2,000 | 91/45 | 6,164 | 1,400 | 84/42 | 3,360 | 6,960 |

| FS-1004H/V | 20-24 | 500-600 | 13,209 | 3,000 | 113/57 | 11,007 | 2,500 | 113/57 | 7,705 | 1,750 | 106/53 | 3,680 | 8,280 |

| FS-1204H/V | 20-24 | 500-600 | 15,850 | 3,600 | 136/68 | 13,209 | 3,000 | 136/68 | 9,246 | 2,100 | 127/63 | 3,830 | 9,030 |

| FS-1406H/V | 20-24 | 500-600 | 18,492 | 4,200 | 170/85 | 15,410 | 3,500 | 170/85 | 10,540 | 2,394 | 158/79 | 5,200 | 11,600 |

| FS-1806H/V | 20-32 | 500-800 | 24,216 | 5,500 | 204/102 | 19,813 | 4,500 | 204/102 | 13,209 | 3,000 | 190/104 | 5,500 | 13,300 |

| Turbo Multi Screen Filters | |||||||||||||

| FS-603H/V-T | 16-18 | 400-500 | 9,246 | 2,100 | 102 | 7,925 | 1,800 | 102 | 4,843 | 1,100 | 95 | ||

| FS-804H/V-T | 18-20 | 450-500 | 12,328 | 2,800 | 136/68 | 10,567 | 2,400 | 136/68 | 7,045 | 1,600 | 127/63 | ||

| FS-1004H/V-T | 20-24 | 500-600 | 15,410 | 3,500 | 181/91 | 13,209 | 3,000 | 181/91 | 8,806 | 2,000 | 169/63 | ||

| FS-1204H/V-T | 20-24 | 500-600 | 18,492 | 4,200 | 227/113 | 15,850 | 3,600 | 227/113 | 10,567 | 2,400 | 211/106 | ||

| FS-1406H/V-T | 20-24 | 500-600 | 22,014 | 5,000 | 272/136 | 18,492 | 4,200 | 272/136 | 12,108 | 2,750 | 253/127 | ||

| FS-1806H/V-T | 20-32 | 500-800 | 25,977 | 5,900 | 305/153 | 21,821 | 4,956 | 305/153 | 14,287 | 3,245 | 284/142 | ||

| Super Turbo Multi Screen Filters | |||||||||||||

| FS-603H/V-ST | 16-18 | 400-500 | 10,127 | 2,300 | 136 | 9,246 | 2,100 | 136 | 5,724 | 1,300 | 127 | ||

| FS-804H/V-ST | 18-20 | 450-500 | 13,209 | 3,000 | 181/91 | 12,328 | 2,800 | 181/91 | 7,925 | 1,800 | 169/84 | ||

| FS-1004H/V-ST | 20-24 | 500-600 | 16,731 | 3,800 | 227/113 | 15,410 | 3,500 | 227/113 | 9,686 | 2,200 | 211/106 | ||

| FS-1204H/V-ST | 20-24 | 500-600 | 19,813 | 4,500 | 272/136 | 18,492 | 4,200 | 272/136 | 12,108 | 2,750 | 253/127 | ||

| FS-1406H/V-ST | 20-24 | 500-600 | 22,895 | 5,200 | 340/170 | 21,574 | 4,900 | 340/170 | 13,209 | 3,000 | 317/158 | ||

| FS-1806H/V-ST | 20-32 | 500-800 | 27,078 | 6,150 | 408/204 | 28,619 | 6,500 | 408/204 | 18,932 | 4,300 | 380/189 | ||

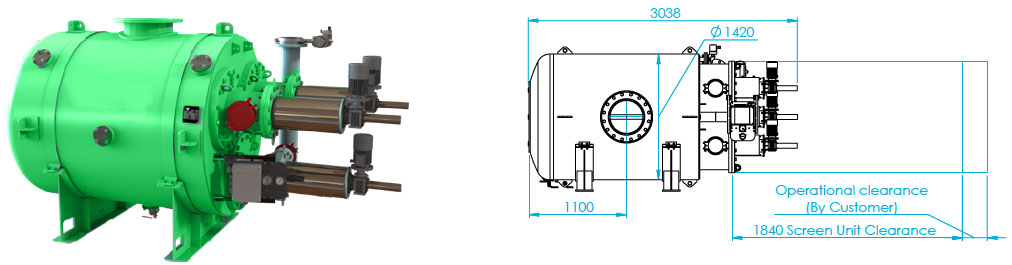

FS-603H/V