Capillary Flow Porometry

Capillary Flow Porometry or Bubble Point Method is used to determine q required pore size for filtration media.

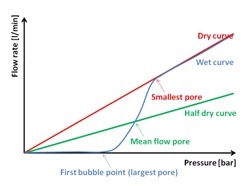

It is based on the fact that, for a given fluid and pore size with a constant wetting, the pressure required to force an air bubble through the pore is inverse proportion to the size of the hole. The theory of capillarity states that the height of a water column in a capillary is indirectly proportional to the capillary diameter.

Surface tension forces held up the water in the capillary and as its diameter gets smaller, the weight in the water column get higher. Water can be pushed back down in a pressure which has the same equivalent height as that of the water column. Thus by determining pressure necessary to force water out of the capillary, the diameter of the capillary can be calculated.

In practice, the pore size of the filter element can be established by wetting the element with the fluid and measuring the pressure at which the first stream of bubbles is emitted from the upper surface of the element.

Methodology

Membrane filters have discrete pores from one side to the other of the membrane, similar to capillary, tubes. The bubble point test is based on the principle that a wetting liquid is held in these capillary pores by capillary attraction and surface tension, and the minimum pressure required to force liquid from these pores is a function of pore diameter. The pressure at which a steady stream of bubbles appears in this test is the bubble point pressure. The bubble point test is significant not only for indicating maximum pore size, but may also indicate a damaged membrane, ineffective seals, or a system leak.

These test methods cover the determination of two of the pore size properties of membrane filters with maximum pore sizes from 0.1 to 15.0 μm.

Advantages

One of the great advantages of the bubble point test is that it can be performed of filters under actual use conditions and with any filter type. It is a non-destructive test, thus it does not contaminate the filter and so can be used to determine the integrity of a filter at any time, as well as establishing the absolute rating.