Multi Plate Screw Press (MPSP)

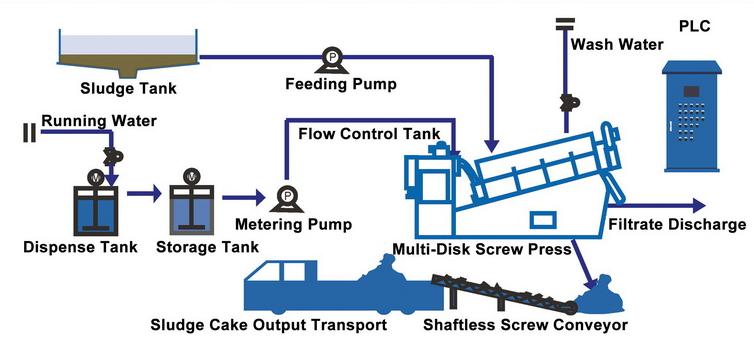

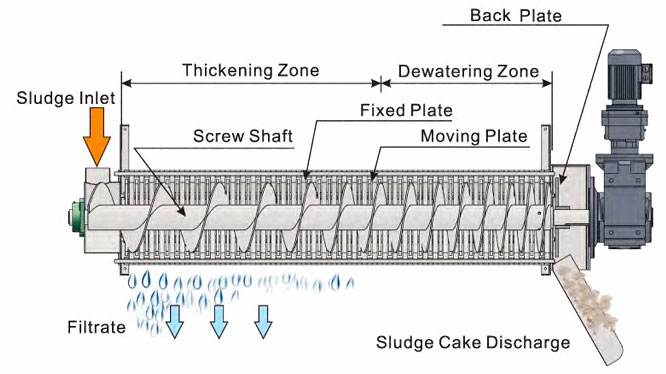

Our multi plate screw press is more advanced than traditional dewatering systems which can be easily blocked by low concentrated sludge. The Ecologix screw press allows for automatic continuous sludge flocculation, thickening, dewatering and filtrate discharging. The thickening zone allows the system to process both highly concentrated sludge as well as sludge with a high water content.

Features

- Exclusive pre-thickening enables a wide solid concentration ranging from 10,000mg/l to 50,000 mg/l

- High efficiency with a small footprint

- Low power consumption (less than 5% of a centrifuge)

- Very low water usage (less than 1% of an equivalent belt filter press)

- Auto start-up, run and shutdown

- Self cleaning

- No blocking or backwash water

- Double nozzles for superior cleaning and rinsing

- Able to handle oily sludge as well as fibrous sludge

- Sealed system = No odors/bad smell

- Wear free

- Sludge flow and cake monitoring system

- Exclusive screw shaft for sludge thickening and inorganic material

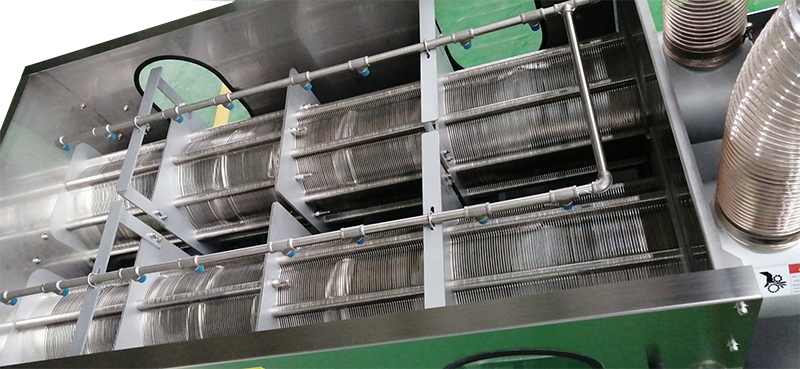

Components

- 304 SS Screw, Shaft, Collection Basin, Flocculation Tank, Main Body

- Sludge thickening & dewatering zone

- Sludge flocculation tank

- Filtrate collection tank

- Automatic / Automated control panel

- Fixed plates and moving plates instead of filter cloth

How It Works

The conditioned sludge flows into the filter chamber from the flocculation tank and is pushed to the discharging end. The thread on the shaft gets progessively tighter as the wasterwater flows through the system, this causes the pressure on the sludge to increase. The water is then separated from the sludge. The movement of the moving and fixed rings cleans the gaps between them and prevents blockage traditionally experienced in similar systems. The filtered sludge cakes are pushed forward by the shaft and finally discharged from the end.

Available Models (SS304 Materials - Metric Measurements)

| Model | Dry Solids Capacity (Kg/h) |

Sludge Treatment Capacity / Water Flow (m3/h) | Dimensions (M) | Weight (Kg) |

Power (kw) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10,000mg/l | 20,000 mg/l | 30,000 mg/l | 40,000 mg/l | 50,000 mg/l | L | W | H | Net | Operating | |||

| MPSP-101 | 5 - 7 | ~0.5 | ~0.25 | ~0.2 | ~0.15 | ~0.14 | 1.850 | 0.74 | 1 | 220 | 315 | 0.36 |

| MPSP-131 | 10 - 14 | ~1 | ~0.5 | ~0.4 | ~0.3 | ~0.28 | 2 | 0.785 | 1 | 250 | 395 | 0.36 |

| MPSP-201 | 15 - 20 | ~1.5 | ~0.75 | ~0.6 | ~0.5 | ~0.4 | 2.5 | 0.9 | 1.3 | 420 | 540 | 0.55 |

| MPSP-202 | 30 - 40 | ~3 | ~1.5 | ~1.2 | ~1.0 | ~0.8 | 2.56 | 1 | 1.3 | 550 | 660 | 1.29 |

| MPSP-301 | 30 - 60 | ~3 | ~2.5 | ~2 | ~1.5 | ~1.2 | 3.33 | 1 | 1.76 | 900 | 1300 | 1.3 |

| MPSP-302 | 60 - 120 | ~6 | ~5 | ~4 | ~3 | ~2.4 | 3.53 | 1.29 | 1.76 | 1350 | 2000 | 2.25 |

| MPSP-303 | 90 - 180 | ~9 | ~7.5 | ~6 | ~4.5 | ~3.6 | 3.68 | 1.62 | 1.76 | 1900 | 2700 | 3.35 |

| MPSP-304 | 120 - 240 | ~12 | ~10 | ~8 | ~6 | ~4.8 | 3.83 | 2 | 1.76 | 2500 | 3600 | 4.1 |

| MPSP-351 | 50 - 100 | ~5 | ~4 | ~3 | ~2.5 | ~2 | 4 | 1.1 | 2.13 | 1100 | 2000 | 1.85 |

| MPSP-352 | 100 - 200 | ~10 | ~8 | ~6 | ~5 | ~4 | 4.39 | 1.65 | 2.13 | 2100 | 3250 | 3.3 |

| MPSP-353 | 150 - 300 | ~15 | ~10 | ~8 | ~7 | ~6 | 4.52 | 1.98 | 2.13 | 3100 | 4600 | 4.8 |

| MPSP-354 | 200 - 400 | ~20 | ~16 | ~12 | ~10 | ~8 | 4.75 | 2.7 | 2.13 | 4100 | 5700 | 5.9 |

| MPSP-401 | 80 - 160 | ~8 | ~6.5 | ~5 | ~4 | ~3.2 | 4.68 | 1.1 | 2.1 | 2200 | 4200 | 2.6 |

| MPSP-402 | 160 - 320 | ~16 | ~13 | ~10 | ~8 | ~6.4 | 4.96 | 1.76 | 2.1 | 3500 | 6000 | 4.5 |

| MPSP-403 | 240 - 480 | ~24 | ~19.5 | ~15 | ~12 | ~9.6 | 5 | 2.58 | 2.1 | 5500 | 8000 | 6.7 |

| MPSP-404 | 320 - 640 | ~32 | ~26 | ~20 | ~16 | ~12.8 | 5.16 | 3.16 | 2.1 | 7000 | 9500 | 8.2 |

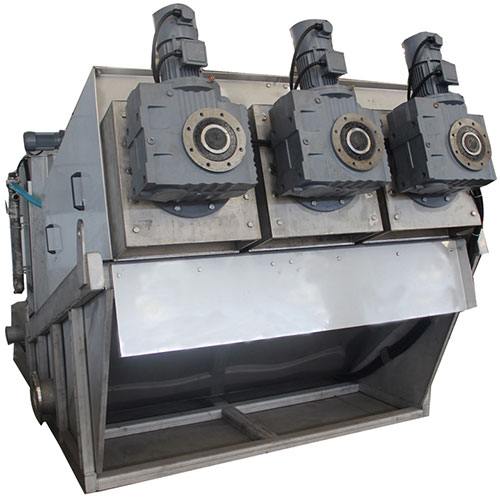

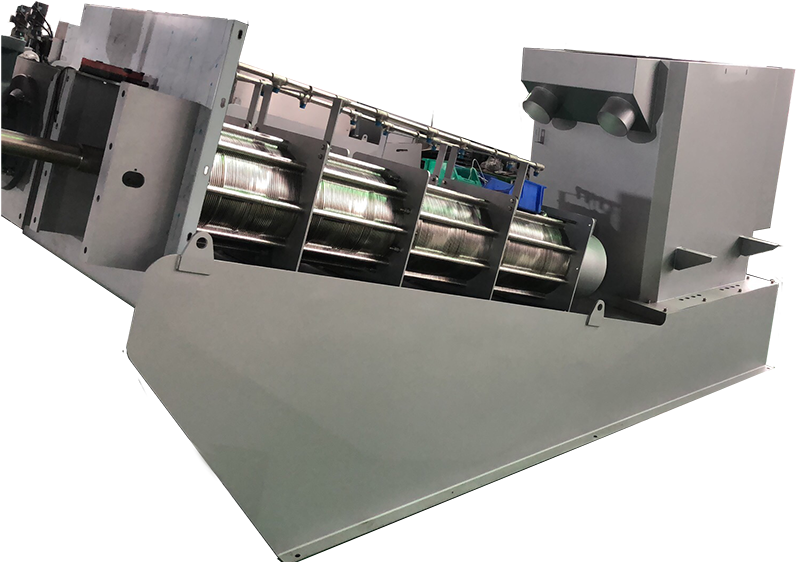

Model MPSP-352 Photos

Sludge Dewatering Results

Applications / Industries

Petrochemical

Paper and Pulp

Food / Beverage industry

Municipal

Biochemical