Dairy Industry Wastewater Treatment

Producing milk, butter, cheese, or yoghurt, using pasteurization or homogenization produces wastewater with high levels of BOD and COD loads and must be reduced before being disharged to municipal treatment facilities. Typical by-products include buttermilk, whey, and their derivatives. Large amounts of water are used during the process producing effluents containing dissolved sugars and proteins, fats, and possibly residues of additives.

Client Testimonial

“We have been very satisfied with the overall install and operational performance of our Ecologix DAF. By far it is the most simple to use and automated DAF system that we have encountered on the market. Ecologix provided an economical turnkey system that has exceeded expectations.” Aaron Riedell, Vice President of Operations at Revela Foods Revela Foods is a diversified food ingredients and processed foods company. Our passion for people and flavor innovation are at the heart of what we do. Our simple approach and efficient systems ensure a seamless, uncomplicated experience from start to finish. Ecologix Environmental Systems has contributed to Revela Foods ongoing mission to harness cutting edge technology in their wastewater treatment operations for the removal of solids and other contaminants (e.g., our cheese dairy production line), by providing Revela Foods with our state of the art Enhanced Dissolved Air Flotation (E-DAF).Dairy Plant Conditions

These effluents have the following characteristics- Biochemical oxygen demand (BOD), with an average ranging from 0.8 to 2.5 kilograms per metric ton (kg/t) of milk in the untreated effluent

- Chemical oxygen demand (COD), which is normally about 1.5 times the BOD level

- Total suspended solids (TSS), at 100–1,000 milligrams per liter (mg/l)

- Total dissolved solids (TDS): phosphorus (10–100 mg/l), and nitrogen (about 6% of the BOD level).

- 1 kg of milk fat = 3 kg COD

- 1 kg of lactose = 1.13 kg COD

- 1 kg protein = 1.36 kg COD

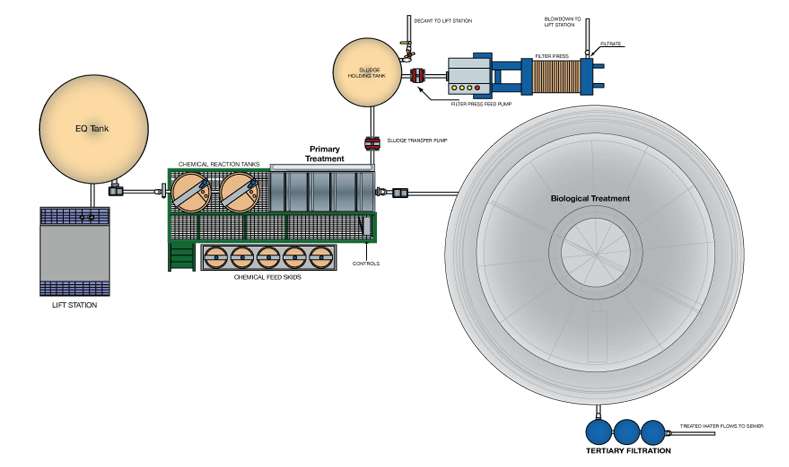

The wastewater may contain pathogens from contaminated materials or production processes. A dairy often generates odors and, in some cases, dust, which also need to be controlled. Ecologix Environmental Systems engineers and builds complete solutions to efficiently manage the wastewater treatment and odor control requirements of the dairy industry. Our solution includes the following benefits:

- Optimization of use of water and cleaning chemicals with option for recirculation of cooling waters.

- Segregation of effluents from sanitary installations, processing, and cooling (including condensation) systems; this would facilitate ability to recycle the wastewater.

- Energy recovery through use of heat exchangers for cooling and condensing.

- Use of high-pressure nozzles to minimize water usage.

The reuse of wastewater from the dairy industry can also be provided for by usage of adsorption and membrane separation among other processes. The color and the odor may be removed completely after activated carbon treatment. The pretreated water can be passed through a cross flow reverse osmosis membrane system and the permeate water can then be reused.

Check our exclusive line of DAF (Dissolved Air Flotation) systems and MBBR systems to handle all your dairy wastewater treatment needs.